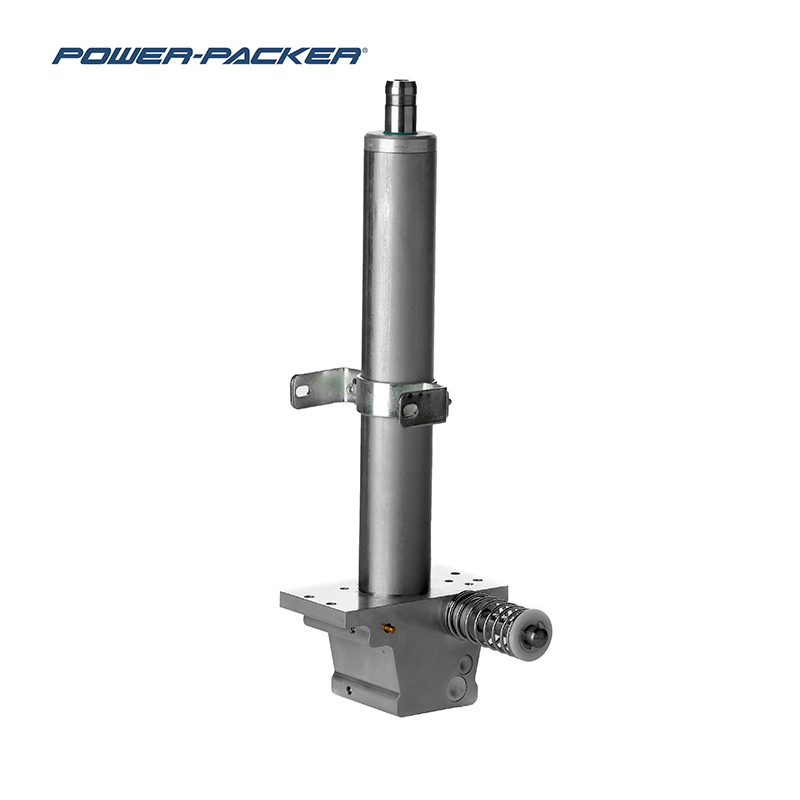

Power Packer Switch Cab Tilt System

Parameters

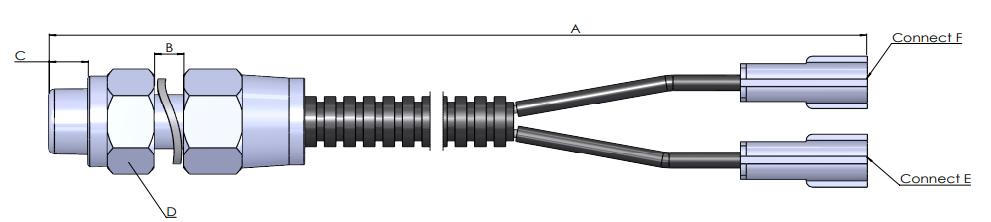

| Product | switch | C (mm) Full stroke | 5 |

| Image |  |

D (mm) | HEX22 |

| Customer No. | WG9925820032 | E Connect | Connect Relay AMP Housing: 174879-2 AMP Holder: 174880-7 AMP Terminal cap: 174880-7 AMP Terminal: 171661-1 |

| Customer | CNHTC | F connect | Connect Power AMP Housing: 174879-2 AMP Holder: 174880-7 AMP Terminal cap: 174880-7 AMP Terminal: 171661-1 |

| Size (mm) A | 420mm | Weight | 0.118+/-10%kg |

| B (mm) Installation width | 4~8 | Others feature | match CPE2-083012 |

Technology / Innovations – E-Pump Switch

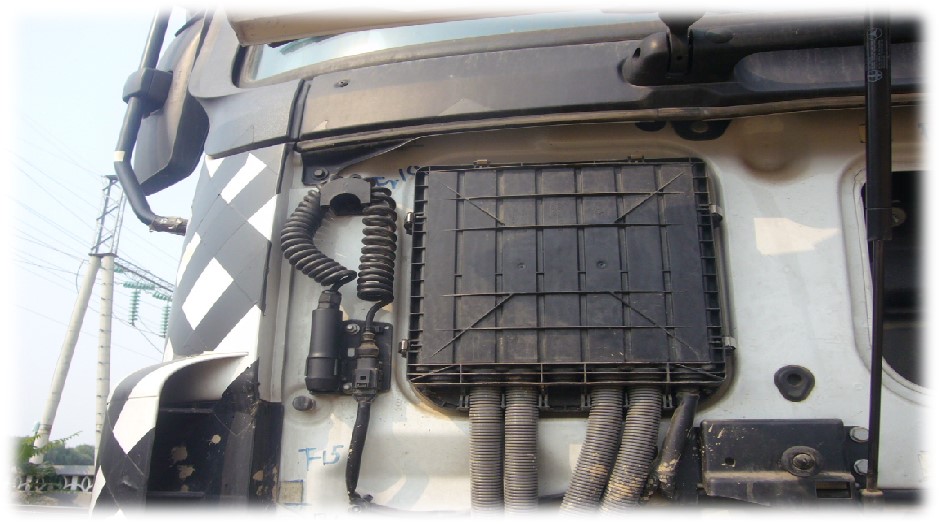

Advantages of pull switch

1) The operator could stand 4 meters away from the front of the truck, much safer, which avoid accidental injury to the operator during the cab tilt.

2) Humanized operation will not feel fingers tired after long-hour working.

3) Better protection, a little water will not affect the switch performance.

4) Better visualization, light up when the switch is turned on, thus operator know the reversing system is running.

Overview

| Sub Parts | |||

| Customer | Power-Packer No. | Customer No. | Truck type |

| CNHTC | CC140903-900 | WG9925820032 | HOWO |

| CC141021-900 | WG9719820032 | HOWO | |

| C170840-900 | WG9X25820030 | HOWO | |

| C130210-900 | 811W41723-6030 | SITRAK | |

| C130218-900 | 811W41723-6032 | SITRAK | |

| C130209-900 | 811W41723-6031 | SITRAK | |

| CC180726-900 | CC180726-900 | SITRAK | |

| C170834-900 | WG9525820143 | HAOHAN | |

| CC110615-900 | WG9525820064 | HAOHAN | |

| C151214-900 | AZ9525820064 | HAOHAN | |

| TATA | C111119-900 | C111119-900 | Prima |

| C111118-900 | C111118-900 | Prima | |

| C111117-900 | C111117-900 | Prima | |

| C111121-900 | C111121-900 | Prima | |

| C111120-900 | C111120-900 | Prima | |

Download

Sales

Power-Packer’s headquarters are in Oldenzaal, The Netherlands where the Product Strategy is located, which includes the Global Sales, Engineering and Marketing departments in addition to that Operations and Logistics.

Working for world markets means being able to operate efficiently as a business partner worldwide – that’s why we have a global footprint of manufacturing facilities across Europe, Asia, North and South America.

Engineering

Power-Packer’s products are custom specific solutions. Therefore, it is very important that the design of each product suits the customer, and has doubtless performance. The main objective of our engineers and production engineers is to design products and production processes in accordance with our customers specifications and our own high standards. Our engineering department consists of specialists who design and innovate hydraulic and electro-hydraulic actuation systems according to customer requirements. The design process is carefully planned and well structured, using common design tools like:

– Function Analysis

– Failure Mode and Effect Analysis

– Design for Assembly

Electronic CAD Data interchange, as well as the possibility of resident engineering, enable intensive and fast communication with our customers. Products are designed in concurrence with their specific production process, which means an optimization of production flow, manufacturing effort and stock usage. At the end, Power-Packer’s products will be well functioning components for reliable end products that are offered by our customers.